PILES INSTALLED

… AND COUNTING

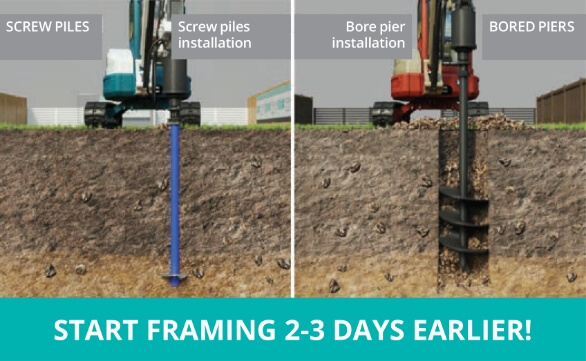

Still using concrete bored piers?

Watch this animated simulation to see which

method is faster.

REASONS TO SWITCH

Fast and easy

to install

No spoil

to remove

If it rains...

no dewatering

Pump concrete

once – not twice

Faster

turnaround

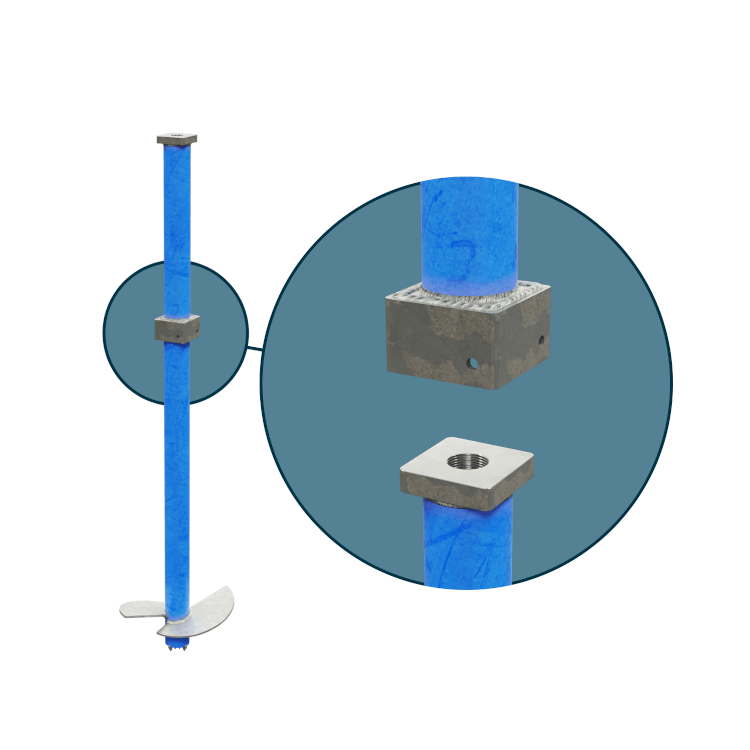

Katana Screw Pile Overview

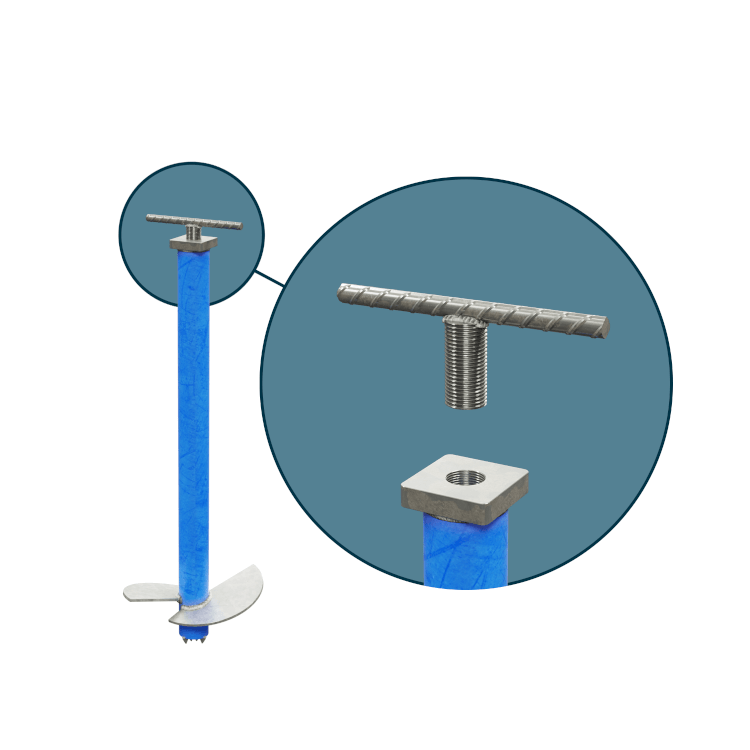

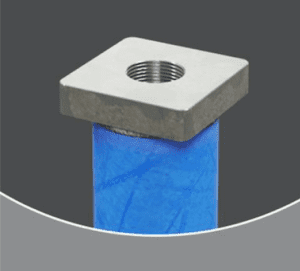

The Top Plate / Drive nut

The top of the pile is capped with a 16mm thick plate with a 36mm threaded hole to accept multiple Katana pile accessories for locking in concrete footings. The top plate, when used with the Katana drive tool, has the safety benefit of engaging the pile to reduce the likelihood of the pile falling out of the drive head during the drilling process.

The Pipe

The pipe section (shaft) is made from Australian made Grade 400 + high-tensile steel. Our thick-walled pipe sections (4.0mm and 5.5mm) means Katana screw piles do not require concrete core filling.

The Twin Helical Plates

The ‘twin-fin’ Katana helix is symmetrically designed to efficiently slice through underlying strata. The result is a screw pile that can be drilled faster and deeper into harder soils with no spoil to remove. The helix diameter ranges from 250mm to 350mm, depending on the pile size.

The Cutting Comb

As the first point of contact with the soil, the cutting comb serves two purposes. Firstly, it makes drilling easier by the design of the teeth and being able to cut through hard material. Secondly, it makes vertical alignment more accurate by the symmetry of the cutting teeth and our twin-fin helical blades.

Applications

Katana Screw Piles are used in residential building foundations, light commercial building foundations, and mining applications.

Some of our more ‘unusual’ installations include the Great Barrier Reef seabed for boat moorings, a NSW lake for a raised floor deck, and a raised floor for a QLD demountable mining camp.

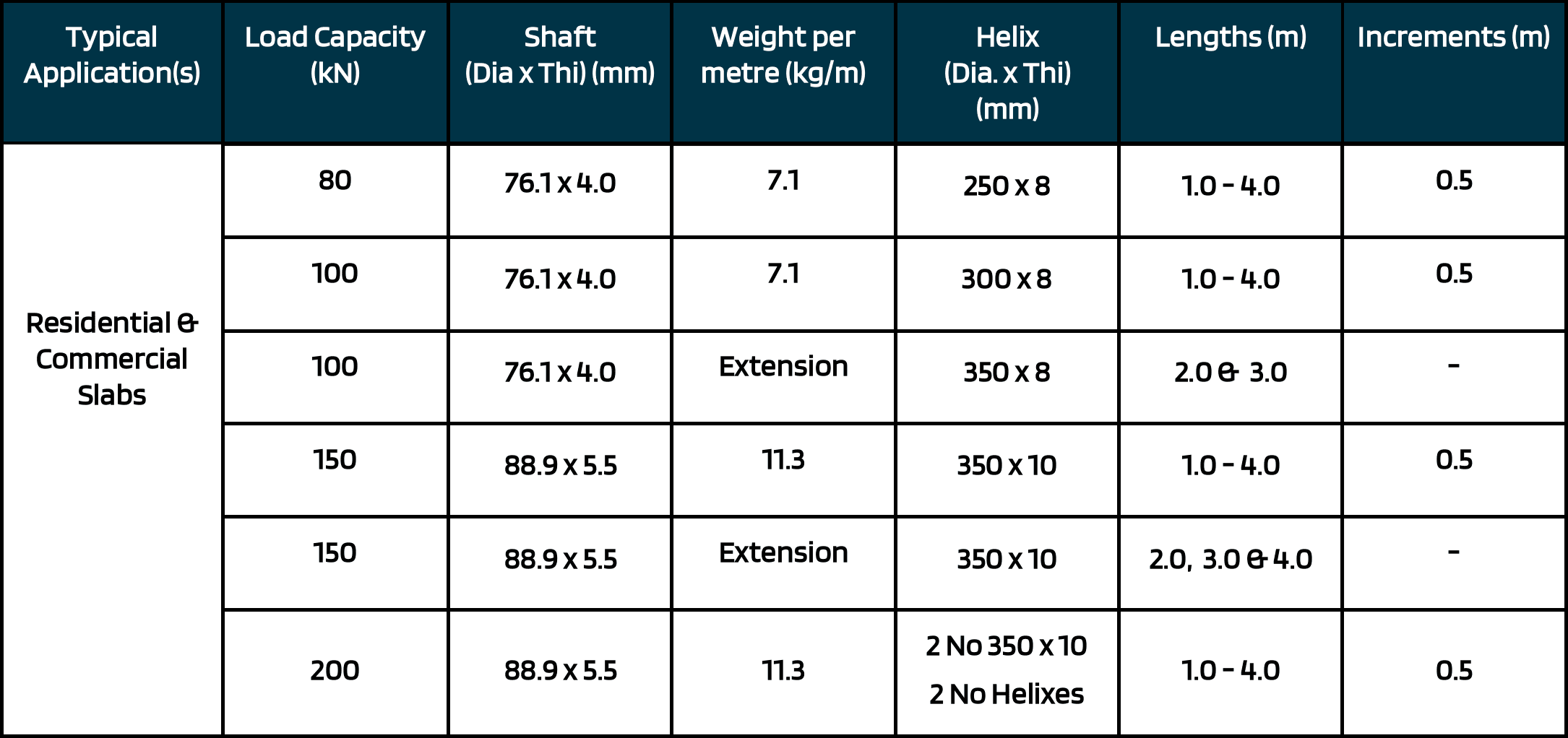

Product Range

Pipe Options

The Katana Screw Pile can be further customised for your application requirements.

Manufacturing

100% Australian made and CodeMark certified! Katana screw piles are manufactured in Brisbane using Australian made 400+ Grade high tensile steel.

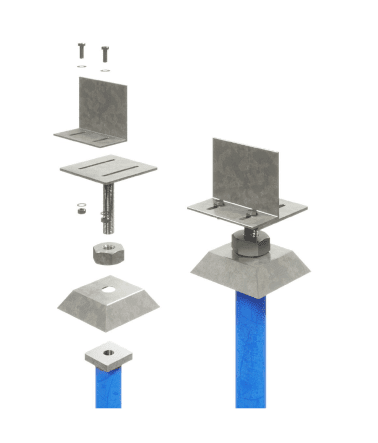

Connectors and Accessories

Katana has innovated a series of connectors and accessories designed to enhance the functionality of the threaded hole in the Square Drive Head. These elements facilitate the versatile use of Katana Screw Piles in various foundation and building applications.

Each component, within this range, has undergone meticulous design and testing, ensuring a seamlessly connected “system” that meets the necessary load capacity and other engineering design requirements. This approach eliminates the necessity for improvised connectors, providing enhanced design certainty.

Require an extension for a pile?

The Katana Pile Extension is utilised when pile lengths exceeding 4.0m are required.

Need the pile to be embedded in the footing?

A 250mm N16 Adjustable Edge Beam Connector is employed for the embedding of the Katana Screw Pile into concrete footings.

Worried about supporting the slab adequately?

Extensive studies conducted with the University of Melbourne affirm that the Katana Square Drive Head at the pile’s top is sufficiently capable of supporting typical slabs.

Looking to cut the pile?

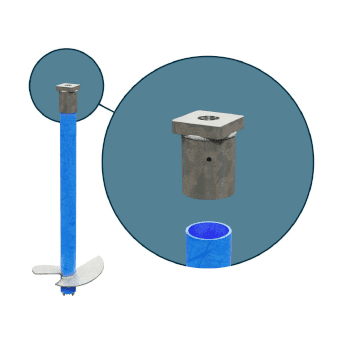

The Katana Cut Drive Nut can be positioned atop the trimmed pile, mimicking the Katana Square Drive Head.

Is the project in need of a raised floor?

Katana provides all the essential connecting bearers to meet any raised floor system specifications.

Is there a particular connector or accessory not mentioned above?

If the application is not covered by the listed connectors or accessories, individuals are encouraged to contact Katana. Katana may be able to create a customer connector tailored to specific foundation needs. Katana is enthusiastic about assisting individuals in exploring innovative uses of the Katana Screw Pile for various building applications.